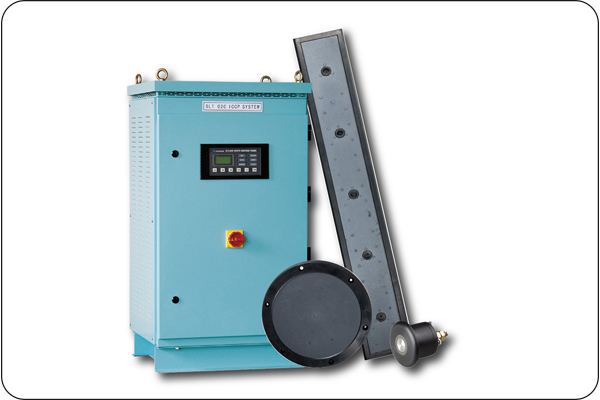

ICCP - Impressed Current Cathodic Protection Systems and accessories

The ICCP impressed current cathodic protection system protects metal structures against corrosion.

The metal surface to be protected is cathodically polarised.

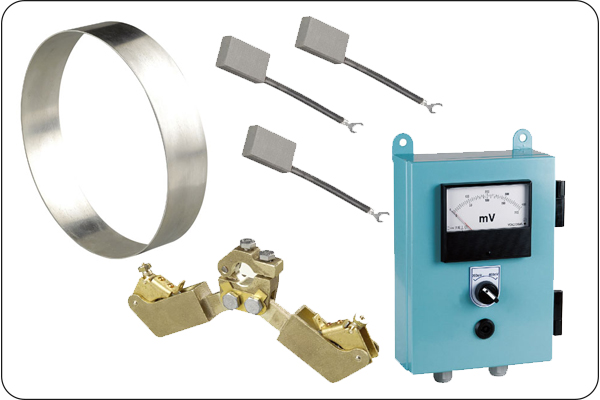

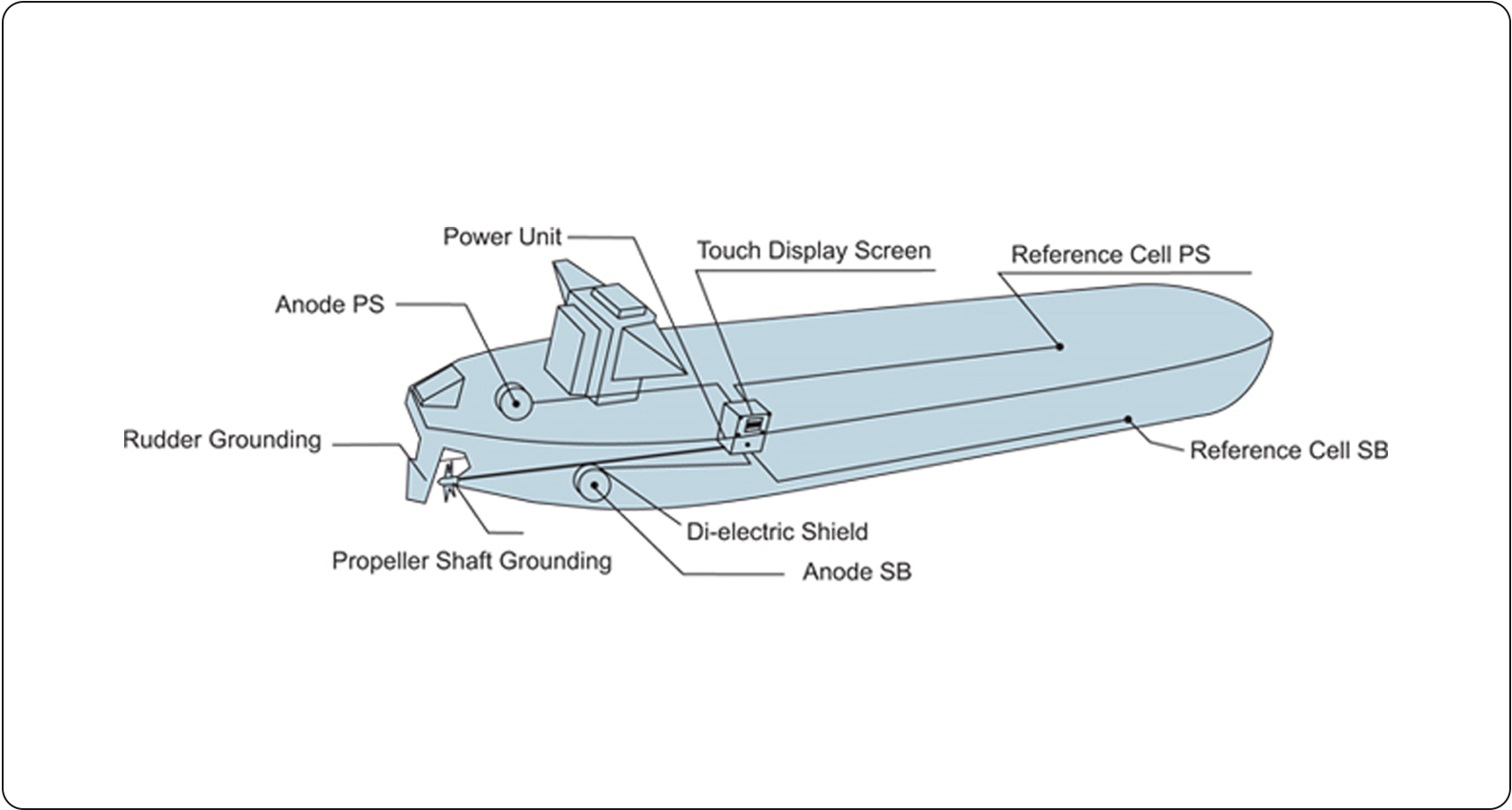

The system is based on control of potential by means of “reference cells”, which automatically govern the impressed current of the permanent anodes which are Platinised Titanium ( Pt Ti )/ Mixed Metal Oxide ( MMO-Ti). The reference cells are normally made of zinc (Zn) or silver/silver chloride (Ag/AgCl).

In the case where continuous monitoring of the platform potential is required, permanent potential monitoring equipment including the monitoring anodes and monitoring instruments can be installed on the platform.

An essential feature of Impressed Current Cathodic Protection (ICCP) systems is that they constantly monitor the electrical potential at the seawater-hull interface and carefully adjust the output to the anodes

The anodes and the reference cells are electrically connected to a suitable electric power supply. Any change in potential measured by the reference cell immediately alters the intensity of the impressed current. The value of the potential is thus maintained around the metal structure’s immunity value.

By installing an ICCP system, operators can make significant cost savings in hull maintenance and achieve reductions in fuel costs by having a smooth hull surface. Furthermore, the system will safeguard the owner's investment and ensure greater safety through stronger hull integrity.

With our expertise we can also support on very stringent ICCP requirements for Naval ships.

SVM can supply shaft-grounding systems complete with slip rings, silver graphite brushes, brush rigging and as well as the Control system which is an Electronic Unit called ACTIVE SHAFT GROUNDING SYSTEM.